ZQ Photoelectric

ZQ Photoelectric offers different solutions from High-Definition EO Cameras and Hi-Res IR Cameras.

Modern wind turbine generators are continuously increasing in size and rated capacity. Larger turbines, slimmer designs and new components help to reduce loads, but also place greater demands on the inspection systems.

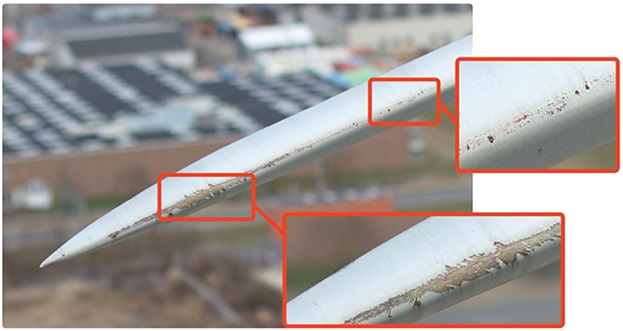

Blades play a vital role in wind turbine system performances. However, they are susceptible to damage arising from complex and irregular loading or even cause catastrophic collapse, and they are expensive to maintain. Defects or damages on wind turbine blades (WTBs) not only reduce the lifespan and power generation efficiency of the wind turbine, but also increase monitoring errors, safety risks and maintenance costs.

By integrating the drone’s flight points to the UAV is capable of performing autonomous IR inspections even during night-time.

EO61

To inspect a transmission line it is necessary to use different technologies, one of which is the traditional optical inspection. With the newest UAV technology, now it is as simple as sending a drone to the field and recollecting some visual data. However, the payload attached to the UAV can make the difference.

IR19T

One of the most used methods used in the wind turbines inspections is the infrared + UAV inspection, that is able to detect hotspots that might point-out a defect in the installation.

ZQ Photoelectric's IR payloads offer two different resolutions, the IR9T and IR19T, resolution (640x512 and 1280x1024). The IR19T is 400% higher than any other IR payload currently in the market, offering a more accurate and clear image for analysis.